-

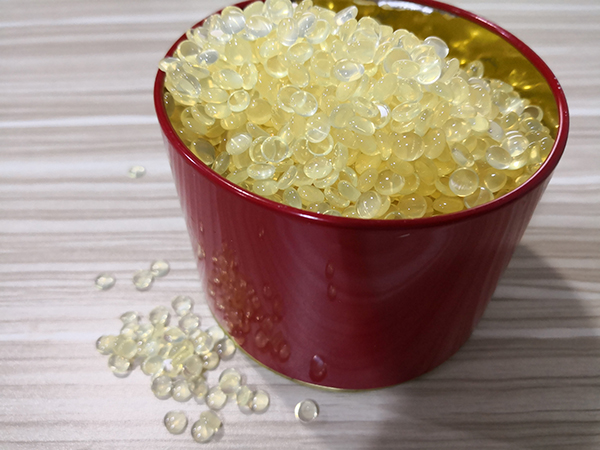

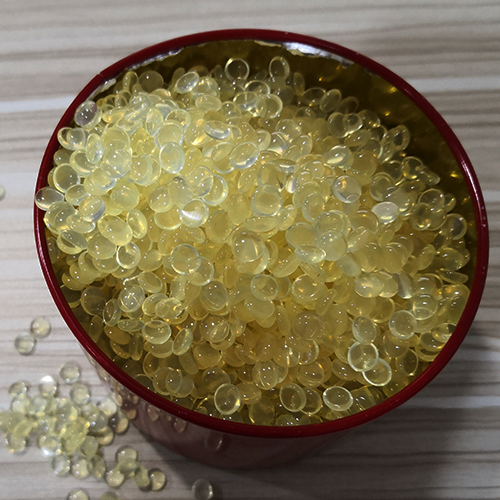

POLYMELT 756 黑色颗粒

POLYMELT 756 为低黏度、高分子量热熔型聚酰胺树脂,主要针对低压模塑成型所设计开发,可溶于一般醇类或苯类之混合溶剂,其树脂主要特性为脱模成型时间快、物性上具有优良的机械强度,及耐热性、柔韧性佳等。可应用于多种材质的接着、电子零件保护、汽车工业。 -

POLYMELT 756 琥珀色颗粒

POLYMELT PA 756 high performance thermoplastic polyamide is designed to meet low pressure molding process requirements. This product can be processed at low processing pressure due to its low viscosity, allowing encapsulation of fragile components without damage. This material produces no toxic fumes in process and provides a good balance of low and high temperature performance.

产品列表 Products

-

2020-01-04 POLYMELT PA756 - TDS(EN).pdf

끂547 166.57 KB -

2020-01-04 POLYMELT PA558 - TDS(EN).pdf

끂379 166.64 KB -

2020-01-04 POLYMELT PA269 - TDS(EN).pdf

끂312 168.24 KB -

2020-01-04 POLYMELT PA265 - TDS(EN).pdf

끂330 168.27 KB

POLYMELT 产品

|

Polyamide (PA) 聚酰胺热熔胶 “Polymelt”用于电子成型的封装材料是基于自然脂肪酸、二聚酸的热塑性热熔胶粘剂。天然无毒无公害,可生物分解,可回收利用。 所有Polyamide (PA) 聚酰胺材料都具备共同的优点,包括防水性封装、与多种基底卓越的粘接性、对多种环境刺激极佳的抵抗性、低粘度、高绝缘强度以及低温条件下更高的灵活性。这些天然原材料保持了宽广的工作温度范围(-50℃/+170℃),符合UL标准及RoHS/REACH环保规范。

|

| Grade 品名 |

Appearance | Softening |

Viscosity 黏度 |

Elongation 抗张伸长率 |

Yield Point 抗张强度 | Water Absorption 吸水率 | Application Temperature 最适应用温度 (℃) |

| POLYMELT 558 | Amber Black |

160±5 | 300~850 cP @ 200 ℃ | 150% | 49kgf/cm² | 2.9% | 180~200℃ |

| 较高的软化点、低黏度、有适度之剥离接着强度、适于含有塑料之电气零件的接着、如变向线圈。 Low viscosity, For deflection york, UL94V-O. |

|||||||

| POLYMELT 241B | Amber Black | 100±5 | 11,000~20,000 cP @ 200 ℃ | 700% | 99kgf/cm² | 0.9% | 180~200℃ |

| 高分子量型、韧性强、低温仍然具柔韧性、适合做PVC热收缩接着。 High molecular type, With very good toughness even in the low temperature. Suitable for PVC heat shrinkable cable closure. |

|||||||

| POLYMELT 241F | Amber Black |

105±5 | 11,000~20,000 cP @ 200 ℃ | 650% | 93kgf/cm² | 0.5% | 180~200℃ |

| 高分子量型、韧性强、低温仍然具柔韧性、适合做PVC热收缩接着。 High molecular type, with very good toughness even in the low temperature. Suitable for PVC heat shrinkable cable closure. |

|||||||

| POLYMELT 265 | Amber Black |

145±5 | 2,000~4,000 cP @ 200 ℃ | 450% | 110kgf/cm² | 0.6% | 180~200℃ |

| 高分子量型、高耐热性、接着性、柔韧性佳、Open time长。适用于各种材料接着。 High molecular type,Good mechanical strength, Heat resistance, Flexibility and long open times, Suitable for bonds to many different substrates including PCB parts, Metals, Plastics, Leather and fabric. |

|||||||

| POLYMELT 269 | Amber Black |

175±5 | 3,000~4,000 cP @ 200 ℃ | 500% | 100kgf/cm² | 0.5% | 200~220℃ |

| 高分子量型、可溶于一般醇类或苯类之混合溶剂、具有优良的机械强度及耐热性、柔韧性佳、应用于电子零件保护、汽车工业、电池封装。 Good mechanical strength, Heat resistance, Flexibility and good wetting properties, Suitable for insulation of electrical parts, Mechanical protection, Automotive industry, Low pressure molding. |

|||||||

| POLYMELT 756 | Amber Black |

185±5 | 3,000~4,000 cP @ 220 ℃ | 500% | 90kgf/cm² | 0.6% | 220~240℃ |

| 高分子量型、可溶于一般醇类或苯类之混合溶剂、具有优良的机械强度及耐热性、柔韧性佳、主要针对低压模塑成型所设计开发。 Good mechanical strength, Heat resistance, Flexibility and good wetting properties, Suitable for insulation of electrical parts, Mechanical protection, Automotive industry, Low pressure molding. |

|||||||

|

|||||||